GlockCNC.com Store

Headstock and Motor Upgrades for Taig Mills & Lathes AND for Sherline Mills & Lathes

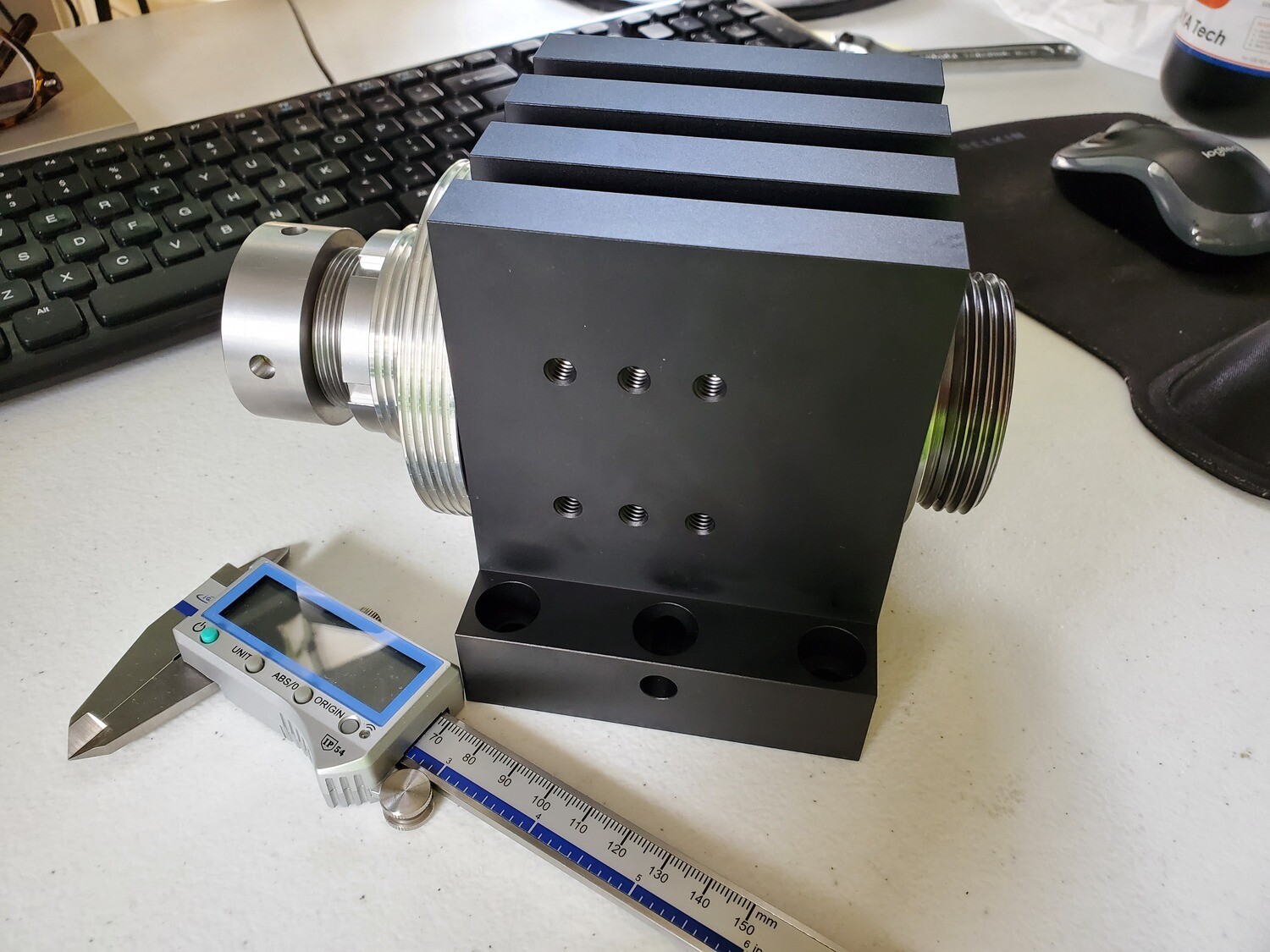

5C Headstock Sherline Taig Lathe

NOTE: Prices will be going up substantially November 10th because of rising costs and changing to higher end suppliers. Currently we are about out 12 weeks out on filling orders for these.

NEW 5C Small Lathe Headstock - Perfect For Sherline, Taig & Other Small Lathes

The GlockCNC 5C is perfect for the guy who wants the precision collet chuck capacity from tiny 1/32" to over 1" and...or even more with the 1.251" (31.78mm) through hole when using a jaw chuck. For many, just the upgrade to bigger chucks will be a dream come true...to use a 5" or 6" jaw chuck on their small lathe. Plus, at those chuck sizes, more super precision chucks are available.

5C Collets - Imagine being able to use a collet to hold round, square or hex stock with great precision and stock size. Here are the range of

collets (taken from Maritool and Hardinge):

Round - 1/32" to 1-5/32 (.016" to 1.1563") Metric - .5MM to 27MM

Hex - 1/8" to 7/8" (.0625" to .875") Metric 1.5MM to 23MM

Square - 1/8" to 9/16" (.125" to 9/16") Metric 2MM to 19MM

There's also rectangle collets, Brown & Sharp and Mores Taper versions, stepped, external expanding arbor type and dead length and

more. Plus, there are even more adapters and specialty options on the market...almost too many to mention. It really opens up a whole new world of metal working for the small lathe guy.

Made From Solid 6061 Aluminum Billet - Of course, the images and video show the 3D printed version. You'll be getting a

nice chuck of precision milled 6061 aluminum anodized in black. There's enough "meat" on this headstock to dampen vibration and if you need to do some custom drilling and tapping into the headstock, you can do that too.

Jaw Chucks - Until now, this has really been a sorely lacking area for small lathes. Sherline and Taig have very limited chuck options...and their chuck precision and holding ability isn't real great. Many have complained that when cutting harder metals, the material comes lose too easily. The biggest complaint though, is the accuracy. Simply put, unless you've found some rare Swiss or German tiny chuck to adapt to the Sherline or Taig, you're stuck with .003" or worse runout in most cases. Commercially available high precision chucks generally start at the 5" or 6" chuck size. At this size, you can even get set-tru type chucks with .0005" repeatability! Unfortunately, the Sherline and Taig lathes won't handle those chucks and their weight. Their bearings are just too small. It really requires a twin bearing front end setup to handle the load...and that's exactly what we did. You'll be getting dual 80MM OD bearings to hand all the load you can through at a smaller lathe. Jaw chuck adapter plates will be available shortly after the headstocks are delivered. (The headstock is 58.5MM from base to the center of the spindle, risers are in the works, but not ready yet)

Large Through Hole - Another big complaint with small lathe owners is the spindle through hole size. Sherlines simply doesn't offer any large through hole models. Taig does have a headstock with a good through hole size, but it won't accept a backplate for chucks. With the GlockCNC 5C headstock, you now have the best of all worlds. A large 1.30" through hole and the ability to use a bigger commercial grade chuck. This greatly enhances what your lathe can now do.

High Precision Workholding - One of the wonderful things about 5C work-holders, is that, it's virtually everywhere. It's a standard in the world of lathes. Plus, you can get inexpensive collets with .0006" runout or high precision collets with just .0002" runout. Your total TIR will depend upon your bearing choice. The ABEC-5 bearings will get you .0005" or better spindle TIR.

Simple Draw Tube - Your new headstock will come with a draw tube to pull the collet tight. A lever closer will be available in the future, but we don't have an estimated date on that yet.

Dual Bearing Front End - Larger stock and larger jaw chucks require a more robust bearing setup. This means you won't have to worry about what kind of weight or pressure you're putting on your headstock system. The bearings are 80mm OD x 50MM ID. Available in ABEC-5 and ABEC-7 precision grades.

Fits About Everything - The headstocks are a direct fit for Sherline products and we offer an adapter for Taig lathes. Because of the flanged sides, you can also easily adapt this to other lathes.

In A Nutshell..... Imagine turning your lathe into a commercial grade cutting machine...that in a nutshell is it. Your new headstock will solve many of those major limitations of your small lathe.

The 5C Small Lathe Headstock Everybody Has Been Waiting For!

Finally, a 5C jaw chuck ready headstock for all smaller lathes! Imagine upgrading your lathe to 5C and the capacity you'll now have. The GlockCNC 5C headstock has some impressive features you won't normally find on a small lathe headstock. It's build is far more robust than the Taig 5C and is threaded for jaw chucks. This is a commercial grade headstock and will be made from a solid chuck of 6061 Aluminum...no hobby grade parts or design here. Keep reading and watch the video for the full scoop.

For Complete Details About The 5C Headstock, Click This Link > https://glockcnc.com/5c-headstock-jaw-chuck-ready-sherline-taig/

Other Info - Distance to center is 58.5mm (2.303")

GlockCNC 5C Headstock Options

Wide Bearing Variety - So here's the breakdown of choices:

ABEC-5 Sealed Deep Groove Come Standard, 6,000RPM

ABEC-5 Sealed Angular Contact Bearings, 12,000RPM

ABEC-7 Sealed Deep Groove For High Precision, Twice As Accurate As ABEC-5, 6,000RPM

ABEC-7 Sealed Angular Contact Bearing for High Precision & Speed, 12,000RPM

Ribbed Pulley - Currently, we only offer the ribbed pulley option. For Sherline users, we do recommend upgrading from the Sherline OEM motor. It's just a weak motor and you'll likely burn it out. For Taig lathe users, you may be able to use the OEM motor with the Sherline type 2 step pulley....however, keep in mind, that the Taig motor will be weak for this grade of headstock. We highly recommend the ribbed belt option and a motor upgrade if it's in your budget.

Taig Lathe Adapters - Currently, we offer an adapter for the gang tool and micro-lathe.

Chuck Plates & Risers - Chuck backplate and riser info and price will be made available closer to the headstock deliver date

About Bearings

After you've picked out what headstock you want, your bearing choice is probably the most import decision you'll make. Bearings are at the heart of the headstock system and where much of the work happens. Of course, everybody's budget is different and you'll want to get what's right for you. Many choose to invest in the best bearings than can afford from the start. In part, this is because we heat-shrink the bearings onto the spindle....so, if you later decide that you want different bearings...it's some real work to swap them out. That extra labor means it will definitely cost more for a bearing upgrade later on (especially if you do it yourself and damage the bearings or spindle in the process). I'm not trying to twist your arm here on what to get...I'm simply telling you what most people do. So here's a basic break down.

For your reference, ABEC ratings define the accuracy of the bearing. The higher the number the better.

ABEC-5 - Deep Grove Bearings - These are the standard bearings that come with the headstock. They are very good bearings and will offer many years of good service life. If you want to stay within the ABEC-5 accuracy range but might run higher speeds, then many opt for the ABEC-5 angular contact bearings.

ABEC-7 Deep Groove Bearings - Do you want to add a new level of precision? ABEC-7 bearings have about twice the level of accuracy of the ABEC-5. If you've been around the machine world for awhile, you probably know that pretty much all precision commercial machines use ABEC-7 bearings. If you don't plan on doing any high speed machining, these deep groove bearings are an excellent choice for great accuracy.

ABEC-7/9 Angular Contact Bearings - For the ultimate in precision, speed and long life...angular contact bearings are the way to go. We stock ABEC-7 steel angular contact bearings. Hybrid ceramic/steel and ABEC-9 bearings are available and generally take about 3 weeks to get. For angular contact bearings, your new Glock 5C or BT30 will have a dual stack of bearings at the tool end. They are arranged in what is called DB orientation (the bearings are back-to-back). This creates excellent load rating and stiffness.

Which Bearings Are Best? - If you're doing low speed work, then deep groove ABEC-7 or ABEC-9 bearings are great. ABEC-9 are awesome and are very rare to find in a headstock like this. If you're going to step up to the plate and invest in ABEC-9 bearings, then you really should opt for a secondary grind operation...this is where the spindle is ground while mounted in the headstock. That way the spindle tapper is very close to the actual bearing runout. This setup is the ultimate in precision. For bearing type, in general, I like angular contact bearings the best. You'll get better speeds, thermal characteristics, longer life and better accuracy on some operations.

What about ceramic? - I know the hybrid steel-ceramic bearings aren't cheap, but they are hands-down the best. It's what you'll find in high end commercial machines. Why do people love them? The biggest reason is their ability to handle heat so well. The ceramic balls are very slippery, and won't transfer heat or expand like steel balls. Steel ball bearings can expand with heat. This puts more pressure on the bearing races and the balls...this is especially the case with "captured" bearings that don't have room for expansion. If you can afford it, many feel that the hybrid ceramic-steel angular contact bearings are hands-down the best...and in my experience, I have to agree.

This is our Temporary Website while we switch servers. Around August 11 our server went haywire for some reason. Anyway, the normal website should be up with 5 days days or so.

James Dimond

Mad Scientist & Engineer

Initially, we started building very specialized superchargers for performance applications. After buying some Sherline products, we pretty much found out that they are very much hobby grade products....but, had some potential. From there we built our own high-end headstocks, then motors and then did the same for Taig mills and lathes. Today we sell commercial grade equipment all over the world.

Contact Us: 269-743-1919