GlockCNC.com Store

Headstock and Motor Upgrades for Taig Mills & Lathes AND for Sherline Mills & Lathes

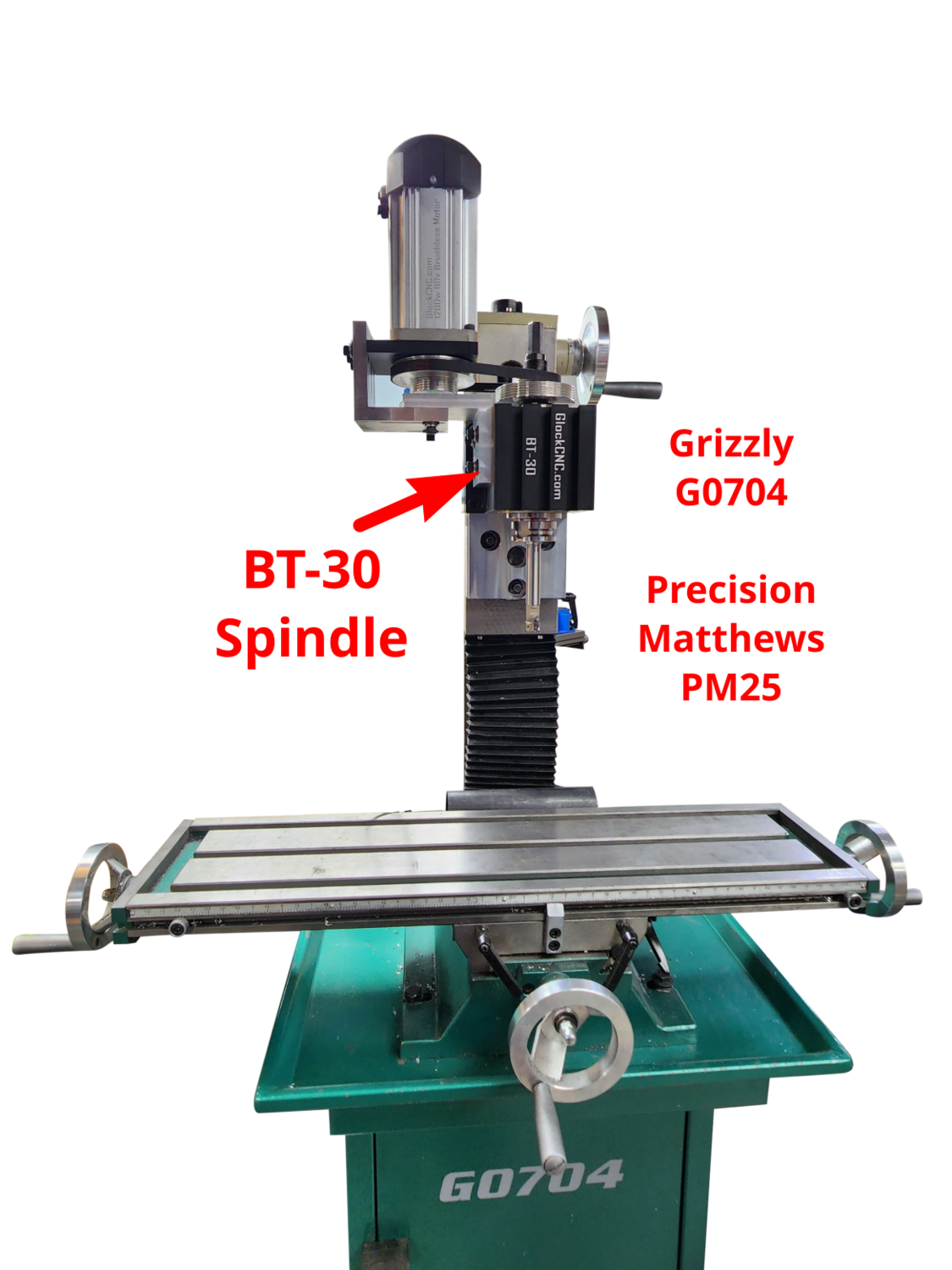

BT30 Spindle Headstock For PM25, BF20 or G0704

NOTE: Prices will be going up substantially November 10th because of rising costs and changing to higher end suppliers. Currently we are about out 12 weeks out on filling orders for these.

Looking For A Major Upgrade to Your Precision Matthews PM25, BF20 or Grizzly G0704?

Introducing The GlockCNC BT-30 Spindle Headstock!

- Use Manually or as Automatic Tool Changer

- Gain 5" of Z Axis Space

- Tooling Taper Seats Inside Bearings for High Rigidity

- Tons of High Precision BT30 Tooling Available

- Perfect Upgrade for Manual or CNC Conversion Kits

- Upgraded Motor Options

Are you looking for a headstock capable of high precision, Automatic Tool Changing, rigid and gives you more Z axis space? Do you like the idea of quickly changing out tools? Then this is for you... Until now, there were no bolt on headstocks that allowed for commercial grade 30 taper tooling to you PM25, BF20, G0704 or similar mill. One of the great parts about owning a BT-30 headstock is the tooling availability. BT-30 tooling is pretty inexpensive for extremely high precision, tons of tooling types available and even lots of great quality used BT-30 tools available, if you want to go that route.

Triple Your RPM...Or Much More

The stock Grizzly G0704 and Precision Matthews PM25 do around 2,500RPM. Unfortunately, this is a bit slow for aluminum and even some steel cutting. By upgrading to the BT30, you now have a wide range of speed options. The standard deep groove bearings are good for about 8,000RPM, the angular contact for about 15,000RPM and the hybrid steel ceramic angular contact bearings for about 25,000RPM. This opens up a whole new world of machining capacity for your mill. You can now get better finishes and cut way down on how long cuts are taking you. The higher speed benefits alone are a huge upgrade to your mill.

Is There Any Advantage to the BT-30 System Over the R8 System?

We’ve done plenty of testing to answer that very question. As it turns out, there’s better vibration dampening, better finish quality and more precision...and here’s why;

Long Tool Taper - By using two good size Internal Dimension stacked bearings, we were able to fit almost the entire BT-30 tool taper up inside the bearings (a 3rd bearing holds the tail section of the spindle arbor). This my friend, puts the tooling load inside of the bearings, where all the work is being done...and frankly, that’s where the taper should be, high up into the bearings. (Take a look at the first image up to the right side on this page. See how far the tooling taper goes into the bearings? It actually goes a little further than what is shown, the 3D printed plastic spindle arbor shrank a little and didn't allow the tool to seat as far up as possible.) This is a significant advantage over an R8 spindle arbors. Most R8 spindles arbors hold the collet or tooling below the bearings...which is exactly where you don’t want it...especially on a smaller mill. Because most R8 spindle arbors hang well below the bearings, it acts like a lever putting a heavy angular load on the bearing for sideways cutting.

Tooling Mass - BT-30 tooling is simply more robust than R8 tooling. Some may argue that the taper on both the BT-30 and R8, at the widest point, is close to the same and may not make a difference. However, there's more to the story than taper width. Testing shows the larger tooling mass and far longer taper for the BT-30 results in far better rigidity and vibration dampening. Once the BT-30 tool is seated in the spindle, the entire spindle now becomes one nice solid chunk of metal ready to do some real precision work.

Tooling Precision - Nowadays, anybody can find inexpensive BT-30 tooling good from 0.0001” to 0.0002” TIR (.0025mm to .004mm)...by comparison, most good R8 collets are .0005” to .0006” TIR. That means R8 tooling is 3 to 6 times less accurate than good BT-30 tooling! Simply put, you can find much more accurate tooling for BT-30 systems.

Tooling Variety - True, there is a lot of tooling for R8 spindles. However, your new BT-30 headstock will open you up to even more tooling options..including modular cutters. Plus, as mentioned before, the tooling offers much more precision than comparable R8 tooling.

Made From Solid 6061 Aluminum Billet - Of course, the images and video show the 3D printed version. You'll be getting a nice chuck of precision milled 6061 aluminum anodized in black. There's enough "meat" on this headstock to dampen vibration and if you need to do some custom drilling and tapping into the headstock, you can do that too.

How Does BT-30 Compare to Tormach Tooling System (TTS)

I really like the TTS for those who already have an R8 spindle. It’s a good compromise if that's your only choice. Tormach now has a nice selection of reasonably priced tooling too. I also like the idea of dual contact. They made a nice business centered around the TTS. That being said, many have experienced some real downfalls to the TTS.

Accuracy - As most machinists know, anything added between the bearings and the cutter create error or inaccuracy. TTS uses a flat nose ¾” collet, which adds runout and that holds on to the TTS tooling, which adds more runout. This is called “stacking error". It’s when you stack runout error on top of runout error. This reduces accuracy, reduces cutter life and can create chatter. BT-30 tooling can easily be found with .0001" or .0002" runout and it doesn't require an extra part in-between the tooling and the spindle arbor. This radically reduces the chance for runout issues.

Slip Pullout - If you imagine what an end mill looks like, it looks like a screw. As you know, when a screw grabs into material, the screws helix pulls itself into the material as it’s twisted. The same happens with endmills. Endmills want to pull out of whatever is holding it. Normally, this isn’t a problem. But if the machine starts to chatter, then the grip on the TTS shaft can break and the tool holder is pulled out. Even a small amount of pullout can damage your part, ruin precision, break cutters and so on. Plus, if it creates a gap between the TTS dual contact face and the spindle arbor, you’ll loose the benefits of dual contact and create more angular stress on the hollow pull tube on the TTS tool.

Short Taper and Bearing Overhang - Unfortunately, in most R8 systems, the TTS collet taper is well below the bearings. This is not the optimal design and its especially problematic for smaller mills. All the work really happens in the bearings, so you want the tooling taper to be up inside the bearings if possible. This is solved with your GlockCNC BT-30 spindle. It's low profile means the tooling taper fits up into the bearings.

Short Taper and Bearing Overhang - Unfortunately, in most R8 systems, the TTS collet taper is well below the bearings. This is not the optimal design and its especially problematic for smaller mills. All the work really happens in the bearings, so you want the tooling taper to be up inside the bearings if possible. This is solved with your GlockCNC BT-30 spindle. It's low profile means the tooling taper fits up into the bearings.

What About Dual-Contact With TTS? - I really like the idea of dual contact and it’s a great improvement for R8 users. What we ended up discovering is this; compared to the benefits of TTS dual contact, small mill users are far better off using tooling that has a longer taper that fits well into the ID of the spindle bearings. As previously mentioned, it puts the workload inside the bearings where it should be and provides better dampening than the TTS. What testing has also showed, is that, the solid mass of 30 taper tooling more than outweighs the benefits of the TTS dual contact. Don’t get me wrong, I like the TTS idea and we use it in our R8 products. However, for the small mill user, many hands down prefer the BT-30 tools. You find BT-30 spindles in commercial machines for a reason...

The Quill Compromise

2) That gap also means you're not getting the best energy transfer into the headstock and column for damping vibration. Again, having your bearings and spindle being directly mounted into the headstock casing itself solves that issue.

If you look at larger commercial CNC machines, they aren't mill drill combinations with a quill. Shops have a drill press for those types of needs.

The GlockCNC BT30 To G0704/PM25 Mill Adapter

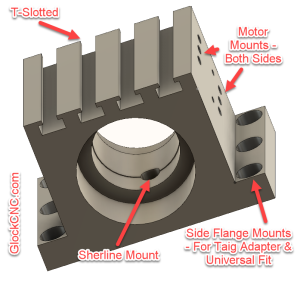

The solution was to use solid billets of aluminum to mount the headstock. These large chunks of aluminum have enough mass to damp the vibration well and maintain very good rigidity. The adapter is made to fit directly to the Z axis dovetail carriage and can be rotated similarly to the OEM headstock, but far easier. (While not necessary, if you want the ultimate in energy management and don't need to rotate the headstock often...you can also drill and tap the Z axis carriage and add more bolt locations to the adapter.)

If you've ever rotated the head on your mill, you know that the OEM headstock makes it a pain to reach the bolt and nuts. Take a look at your headstock adapter for the BT30, the center bolt and nuts are easy to get to. This means you will no longer need to raise the head all the way up and struggle to get to the center bolt and nuts.

By the way, swapping out your old headstock for your new BT30 can be done in 20 minutes or so. Afterwards of course, just like any time you move a headstock, take your time to tram the head square to the mill.

Did You Say More Z Axis Room?

Because of the headstocks compact design, it can be mounted higher on the Z axis carriage. This means your mill has even more capacity..it adds a considerable 5.3" (135mm) of Z axis work room! You now have room for deeper operations, a bigger vice, bigger tooling or just taller parts general. It's kind of like getting an upgrade to your machine frame.

Motor Mounts

For OEM Precision Matthews Motors - A lot of people like these motors and they're worth keeping for sure. With a little drilling, you should be able to use the PM motor and mounts...however, that's based on my observations...we only have a Grizzly machine here in the shop. That being said, just know ahead of time that you might have to do a little bit of figuring to make it work. If you go this route, please show us how you did it and we'll send you a free BT30 ER16 tool holder.

For GlockCNC Motors - All GlockCNC motors bolt directly to the headstock. Currently, we only have the motor mounts that mount on the side of the BT30 headstock. In the coming months, we should have a system to mount the motors behind the headstock. You can then just move the motor over to the new mounts.

GlockCNC BT-30 Headstock Features & Benefits

Both Quick Manual Tool Change & ATC Ready - If you want you can start with the super quick manual tool change option or go to ATC at any time.

More Z Axis Room - You'll be gaining about 5" of extra Z axis room. Which is actually a significant upgrade in work envelope.

Dual Stack Bearings - By using two 75mm OD x 45mm ID bearings stacked on top of each other, it results in better vibrational energy transfer and dampening. For angular contact bearings, it's a matched pair set back-to-back. For a smaller mill, the dual bearings on the cutting end of the headstock can be critical for accurate cuts and good surface finish through reduced vibration. After all, nobody likes machine chatter, right?...

ATC Petal Clamp or Manual Drawbar - You have two choices for securing your tooling. Your first option is simply use a drawbar and the threads inside the BT-30 tooling. Your other option is to use a pull stud with optional petal clamp. Frankly, I recommend starting with the manual drawbar version and just get a good cordless impact driver or midsize cordless impact wrench and 13mm socket for the drawbar. You can actually zip your tool holders in and out about as fast as you could with a pneumatic actuator system...and you won’t need to run air to the spindle by doing it this way. Of course, you can always add the petal clamp anytime you want for ATC. We do sell the petal clamp, however all other parts for the ATC setup will be up to you. There are so many ways to set the ATC up, we simply can't stock what everybody might want.

Additional Note About Using A Drawbar - I want to throw in one other comment about using the drawbar instead of the petal clamp. The drawbar will hold the BT-30 tool with extra solid strength and add to rigidity. Here’s why...because the drawbar screws solidly into the tool, runs the length of the spindle and tightly squeezes against the top of the spindle, it adds leverage and helps dissipate vibration better through the headstock, Z axis carriage and column. This is a real plus for smaller mills. Petal clamps are made only to pull the tool up and keep it there. They will not dissipate energy like a drawbar will.

Gazillions of Tooling Options - From shrink fit endmill holders to larger indexable cutters to modular cutters to ER holders to basic end mill holders...you now have virtually unlimited choices.

Precision - Your new headstock will have .0005” TIR or less. You can upgrade to ABEC-7 bearings and dial the runout down to .0003" or less. Pick up some super accurate tooling and you now have the ultimate mill!

Other Info -

- Distance to center: 52.5mm (2.067")

- Thickness of Taig adapter if needed: 25.4mm (1")

- Bolt Pattern: 155mm x 37.5mm (series of 3 hole are 37.5mm apart)

- Weight with manual drawbar: 8lb 4oz

About Bearings

Bearings are at the heart of the headstock system and where much of the work happens. Of course, everybody's budget is different and you'll want to get what's right for you. Many choose to invest in the best bearings than can afford from the start. In part, this is because we heat-shrink the bearings onto the spindle....so, if you later decide that you want different bearings...it's some real work to swap them out. That extra labor means it will definitely cost more for a bearing upgrade later on (especially if you do it yourself and damage the bearings or spindle in the process). I'm not trying to twist your arm here on what to get...I'm simply telling you what most people do. So here's a basic break down.

For your reference, ABEC ratings define the accuracy of the bearing. The higher the number the better.

ABEC-5 - Deep Grove Bearings - These are the standard bearings that come with the headstock. They are very good bearings and will offer many years of good service life. If you want to stay within the ABEC-5 accuracy range but might run higher speeds, then many opt for the ABEC-5 angular contact bearings.

ABEC-7 Deep Groove Bearings - Do you want to add a new level of precision? ABEC-7 bearings have about twice the level of accuracy of the ABEC-5. If you've been around the machine world for awhile, you probably know that pretty much all precision commercial machines use ABEC-7 bearings. If you don't plan on doing any high speed machining, these deep groove bearings are an excellent choice for great accuracy.

ABEC-7/9 Angular Contact Bearings - For the ultimate in precision, speed and long life...angular contact bearings are the way to go. We stock ABEC-7 steel angular contact bearings. Hybrid ceramic/steel and ABEC-9 bearings are available and generally take about 3 weeks to get. For angular contact bearings, your new Glock 5C or BT30 will have a dual stack of bearings at the tool end. They are arranged in what is called DB orientation (the bearings are back-to-back). This creates excellent load rating and stiffness.

Which Bearings Are Best? - If you're doing low speed work, then deep groove ABEC-7 or ABEC-9 bearings are great. ABEC-9 are awesome and are very rare to find in a headstock like this. If you're going to step up to the plate and invest in ABEC-9 bearings, then you really should opt for a secondary grind operation...this is where the spindle is ground while mounted in the headstock. That way the spindle tapper is very close to the actual bearing runout. This setup is the ultimate in precision. For bearing type, in general, I like angular contact bearings the best. You'll get better speeds, thermal characteristics, longer life and better accuracy on some operations.

What about ceramic? - I know the hybrid steel-ceramic bearings aren't cheap, but they are hands-down the best. It's what you'll find in high end commercial machines. Why do people love them? The biggest reason is their ability to handle heat so well. The ceramic balls are very slippery, and won't transfer heat or expand like steel balls. Steel ball bearings can expand with heat. This puts more pressure on the bearing races and the balls...this is especially the case with "captured" bearings that don't have room for expansion. If you can afford it, many feel that the hybrid ceramic-steel angular contact bearings are hands-down the best...and in my experience, I have to agree.

Options

Ribbed Pulley - You can get our 2 step 5 rib pulley (60mm & 40mm steps) or come up with your own. The ribbed pulley gives you lots of belt brand choices if you need to replace the belt. The belt we supply is good for up to 3,000 watt motors and 10,000RPM.

Petal Clamp and Push-Pull Bar - Steel with hard brass petals for use with 45 degree pullstuds. The petal clamp and push-pull bar is included. However, we're still sourcing the belleville disc spring washers and best pneumatic cylinder. Those aren't included. When we narrow down the best supplier, we'll add disc spring parts and pneumatic cylinder as an option or you can get your own.

High Speed Balancing - You can opt for the 20,000 RPM balanced spindle arbor if you want to ramp-up your cutting. We recommend angular contact bearings for anything over 6,000RPM.

Answers To Common Questions

I see several upgrade options, which ones are the most important? - If it was me, the first thing I would consider is the bearings. If your budget allows it and you want the best of the best, it's hands down the hybrid steel ceramic angular contact bearings with secondary grind. If my budget didn't allow me to invest in the hybrid ceramic bearings, then I would go with the sealed ABEC7 angular contact bearings...these are also the most popular. You might want to watch the bearing video in the buyers guide section of the website.

What is a secondary grind operation? - The secondary grind operation is literally that. All of our spindles have been precision ground when we get them. After we assemble the spindle into the bearings and headstock, a more precise secondary grind can be done. The completed headstock is mounted on a special ID grinder, indicated in and carefully ground for high precision. This typically gets the runout down to 0.0001" or better. It's not cheap, but investing in high precision machines never is.

Can I have the secondary grind operation done at a later time? - Yes, but it will be more expensive. It really is best to have it done when making the initial purchase. But, if your budget doesn't allow it initially, then it doesn't allow it...just do it when you're ready.

Does your headstock have "drive dogs"? - Nope...if a person is twisting so hard on the tooling that the drive dogs need to be used, then it's probably being used far too aggressively. Tooling should not spin inside the taper!

Will we offer a complete ATC system? - Yes, but we simply don't know when. We have a lot going on at the moment, so it will be a while. Plus, that's more inventory we would have to stock. Currently, we're providing the petal clamp as an option and everything else is up to the customer to design.

What's the build time for my BT30 headstock and adapter? - This can vary. Sales are kind of a funny thing...sometimes I'll have inventory and the next minute everybody wants the same thing and we sell out. Call me if you want specifics. At time of this writing, it's taking me a minimum of 4 to 8 weeks to get builds out, depending upon what all is ordered and my current workload. As a rule of thumb, you are far better off getting your order in as soon as possible, regardless of the current wait time...there will be no better time than the present because we often sell out and can even sell out on incoming parts orders.

Do you offer CNC conversion kits? - We do not, but there are several companies that do. We did purchase a conversion kit for our G0704 sometime ago...however, the owner of that company passed away and I don't have any experience with the other available kit companies...so, I can't really recommend one over the other. Arizona CNC and Procut both make kits, but I think there's also one other company out there too.

I haven't purchased my mill yet, should I go with the Grizzly, Precision Matthews or other similar version? - I know all of the mills this size look similar, but they can be very different. We only have a G0704 in the shop, so I haven't had a chance to use the PM25. We do have a PM30 though. What I can tell you is that the quality of the PM30 is better than the overall quality of the Grizzly G0704. If I were to buy a G0704 size mill again, it would be the PM25. I also like how the PM25 column is mounted compared to the G0704. That being said, with some skill the G0704 can ultimately do the same quality work as the PM25.

This is our Temporary Website while we switch servers. Around August 11 our server went haywire for some reason. Anyway, the normal website should be up with 5 days days or so.

James Dimond

Mad Scientist & Engineer

Initially, we started building very specialized superchargers for performance applications. After buying some Sherline products, we pretty much found out that they are very much hobby grade products....but, had some potential. From there we built our own high-end headstocks, then motors and then did the same for Taig mills and lathes. Today we sell commercial grade equipment all over the world.

Contact Us: 269-743-1919