GlockCNC.com Store

Headstock and Motor Upgrades for Taig Mills & Lathes AND for Sherline Mills & Lathes

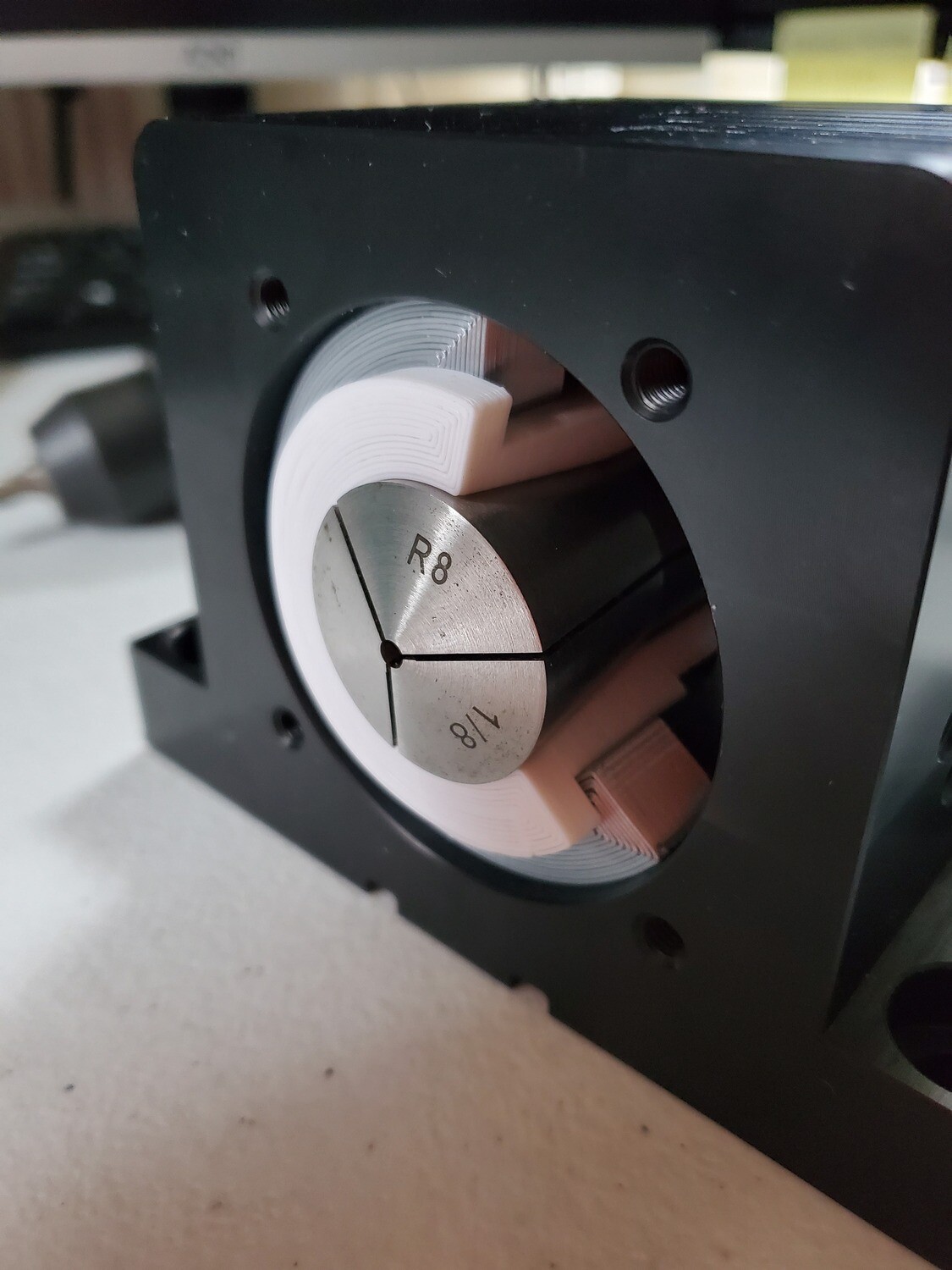

R8 Taig Sherline Low Profile Headstock Upgrade

NOTE: Prices will be going up substantially November 10th because of rising costs and changing to higher end suppliers. Currently we are about out 12 weeks out on filling orders for these.

The Low Profile R8 Is The Best R8 Version...Hands Down

One of the common drawbacks to the R8 is how far the spindle sticks below the bottom bearing. This creates increased pressure on the bearings...and nobody wants that. The obvious issue is bearing wear. The other major problems are precision, dampening and rigidity. The further away from the bearings your cutter is, the bigger those issues become. Because we designed the BT-30 and ISO-20 with a low profile to solve those issues, we figured that we might as well do the same for the R8 systems. This new low profile spindle configuration is a great option for those who already have a big investment in R8 or TTS tooling...or just like the idea of an R8 headstock system. It can add new life to your mill via some of the benefits listed below:

- Taper Location - By using a very short nose, or "stick-out", from the bottom bearing of just 0.20" (5mm) (like the GlockCNC BT-30 and ISO-20), this allows most of the spindle taper to be located inside the bearings. This means your R8 tooling will also sit inside the bearing area. Of course, for you, this produces better rigidity and vibration dampening. Think about it for a moment...the only part of R8 tooling that comes in contact with the spindle is the short taper area...and nearly every other R8 spindle out there places the bearings in an area where there is absolutely no tooling contact with the spindle. That's a HUGE disadvantage for dampening on a small mill and can lead to chatter issues. A low profile spindle is a big plus for the dual contact feature of the Tormach Tooling System if you have it. Your TTS straight shank will be inside the taper/bearing area and the dual contact is closer to the bearing face.

- Compact Design – Because of the short nose spindle, you have maximum Z axis room. For TTS users, this helps off set how far down the tool goes into the Z axis. For those using R8 collets, you’ll really be able to maximize your work envelope.

- Bigger More Accurate Bearings - You'll have far bigger bearings than the OEM Taig or Sherline bearings. Plus, we start out with ABEC-5 deep groove bearings. You also have the option to select ABEC-7 deep groove or angular contact bearings.

- Fast Tool Changes – We’ve decided to eliminate the R8 guide pin and tommy bar. Why? Gone are the days of using a wrench to loosen you R8 tooling. Your new R8 headstock is designed for using a cordless impact driver. If you don’t already have one, you’ll want to pick up ¼” cordless impact driver and 3/8” socket adapter. Using a simple socket with this, you can zip your tooling in and out with ease.

- Robust Headstock Casing - Like our previous model, the headstock casing has a whole lot more "meat" to it than the OEM Sherline or Taig headstocks. This allows for bigger bearings and far better dampening. Too, if you need to drill and tap the headstock for a custom setup, you've got enough headstock material to do that.

- Tons of Tooling – Of course, one of the biggest advantages of using an R8 system is the tooling options. There are tons of new and used R8 tooling available online. From drill chuck adapters to face cutters to boring setups. As many of you know, the Tormach Tooling System is also another option.

How does this compare to our previous R8 spindles? You'll notice a couple of differences right away;

- You'll gain 1.77" (45mm) of Z axis because the new spindle nose is so short. On a small mill this is important. You can now fit bigger parts.

- Much better harmonic dampening. This can mean faster cuts with better finish and precision.

- Shorter length on the pulley side. The old spindle arbor was tall because we thought we might also use it for another headstock, but never did...so, we shortened it to the right size.

GlockCNC R8 Low-Profile Headstock Specifications:

- Material: Cut from Billet 6061 Aluminum

- Dimensions: Main body 3.0"x3.5", Side Flanges 5.07" Wide

- Finish: Anodized Black

- Speeds

- Deep Groove Bearings - 8,000 RPM Max

- Angular Contact Bearings - 18,000 RPM Max

- Distance to Center: 1.75"

- Mounting: Direct fit to Sherline and requires adapter for Taig. Six screw flange sides for custom application.

- Distance from Bottom Bearing to Spindle Nose Bottom: 0.20" (5mm)

- Pulley Options: 14mm ID Ribbed Micro-V or V Groove Sherline Compatible (we like the Micro-V the best by far)

- Motor Mounts: Either GlockCNC motors or Sherline OEM. Can be mounted on either side of the headstock.

For Taig Owners – Taig mills will require our adapter plate. There are some significant advantages to using this adapter with your mill. 1) It uses the entire width and height of the Z axis carriage for maximum rigidity and dampening. 2) No weak tiny dovetail mounting…you’ll now have a nice solid mating surface. 3) Two mounting positions so you can maximize your Z axis working envelope. 4) Built in M14 tapped hole for adapting an AXA lathe tool post. In other words…you can now use the robust qualities of the Taig mill as a lathe.

For Sherline Owners - Sherline has two different size mounting studs. The longer version needs to have 3mm shaved off. The fastest way is to just grind it down a little until the headstock fits properly.

This is our Temporary Website while we switch servers. Around August 11 our server went haywire for some reason. Anyway, the normal website should be up with 5 days days or so.

James Dimond

Mad Scientist & Engineer

Initially, we started building very specialized superchargers for performance applications. After buying some Sherline products, we pretty much found out that they are very much hobby grade products....but, had some potential. From there we built our own high-end headstocks, then motors and then did the same for Taig mills and lathes. Today we sell commercial grade equipment all over the world.

Contact Us: 269-743-1919